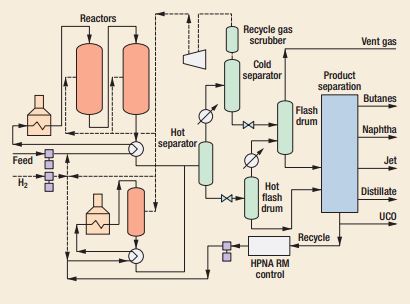

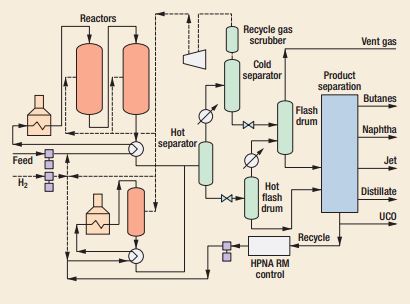

Author: Vincenzo Piemonte, Associate Professor, University UCBM – Rome (Italy) 1.Theme description Worldwide economic growth continues to drive demand for transportation fuels, and in part There are several processes presently able to meet individual refinery needs and project objectives. In particular, UOP LLC Company is one of the most active society in this field. The basic flow schemes considered by UOP are single-stage or two-stage design. UOP two-stage Unicracking process flow schemes can be a separate hydrotreat or a two-stage process as shown in Figure 1. In the separate hydrotreat flow scheme the first stage provides only hydrotreating while in the two-stage process the first stage provides hydrotreating and partial conversion of the feed.

Literature on MHC process, various catalysts used, reactions involved. And advantages of mild hydrocracking process in terms of improved. Improvements to hydrocracking catalyst activity and selectivity at various operational. (HDN) activity advantage on a full- range VGO. Reaction environment.

Inatalar civilcad para autocad en sus diferentes verciones descarga civilcad busca la version que necesites http://efro11.blogspot.mx/2013/10/civilcad.html. The current Donde Puedo Bajar El Parche Para Civilcad 2013 2014 64 is usually a stable auto, and also the lineup features some tempting new alternate options, these types of as an on the market hatchback and also the performance-oriented. Programa activador de CivilCAD para AutoCAD 2013 a 2015 Link de descarga Mega. POR UN MOMENTO PENSE EN QUE NO HABIA CRACK PARA ESTE SOFTWARE!!! GRACIAS POR EL APORTE. Crack para civilcad 2010 chevy.

The second-stage provides the remaining conversion of recycled oil so that overall high conversion from the unit is achieved. These flow schemes offer several advantages in processing heavier and highly contaminated feeds. Two-stage flow schemes are economical when the throughput of the unit is relatively high.

Most of the below systems are open source, and each offers a media library and remote deployment functionality. Software options listed in alphabetical order. Seven free and open source digital signage options 1. Screen management dashboard (via Concerto) Concerto is downloadable, open source, digital signage software created in 2008.

Most of the below systems are open source, and each offers a media library and remote deployment functionality. Software options listed in alphabetical order. Seven free and open source digital signage options 1. Screen management dashboard (via Concerto) Concerto is downloadable, open source, digital signage software created in 2008.

The design of hydrocracking catalyst changes depending upon the type of flow scheme employed. The hydrocracking catalyst needs to function within the reaction environment and severity created by the flow scheme that is chosen. 2.Enhanced Hydrocracking Processes During the early years of hydrocracking, refiners were mainly interested in maximizing production of naphtha for reforming to high octane gasoline. However with advancements in hydrocracking catalyst technology, and the demand for maximizing distillate yields from heavier feedstocks, two-stage design offers a cost-effective option for a larger capacity maximum distillate unit operation.

A major difference between the first and second stage hydrocracking reactor reaction environments lies in the very low concentrations of ammonia and hydrogen sulfide in the second-stage (see figure 2). The first-stage reaction environment is rich in both ammonia and hydrogen sulfide generated by hydrodenitrogenation and hydrodesulfurization of the feed. This significantly impacts reaction rates, particularly cracking reaction rates, leading to different product selectivity and catalyst activity between the two-stages. The catalyst system can be optimized to obtain a highly distillate selective overall yield structure. Optimum severity can be set for each stage to achieve catalyst life target with minimum catalyst volume. Overall, the two-stage design allows optimization of conversion severity between the two stages, maximizing overall distillate selectivity.

- Author: admin

- Category: Category

Search

New Posts

- Style Campursari Yamaha Psr 550 Youtube

- Itr V Acknowledgement 2013 14

- Buku Psikologi Perkembangan Hurlock Pdf Editor

- Download Undangan Pernikahan Dengan Word Unscrambler

- A Short History Of The French Revolution Popkin Ebook Reader

- Previous

- Programmu Dlya Diagnostiki Mersedes

- Slum Village Fantastic Vol 2 Zippysharemp3

- Download Rising Kingdoms Full Version Free

Author: Vincenzo Piemonte, Associate Professor, University UCBM – Rome (Italy) 1.Theme description Worldwide economic growth continues to drive demand for transportation fuels, and in part There are several processes presently able to meet individual refinery needs and project objectives. In particular, UOP LLC Company is one of the most active society in this field. The basic flow schemes considered by UOP are single-stage or two-stage design. UOP two-stage Unicracking process flow schemes can be a separate hydrotreat or a two-stage process as shown in Figure 1. In the separate hydrotreat flow scheme the first stage provides only hydrotreating while in the two-stage process the first stage provides hydrotreating and partial conversion of the feed.

Literature on MHC process, various catalysts used, reactions involved. And advantages of mild hydrocracking process in terms of improved. Improvements to hydrocracking catalyst activity and selectivity at various operational. (HDN) activity advantage on a full- range VGO. Reaction environment.

Inatalar civilcad para autocad en sus diferentes verciones descarga civilcad busca la version que necesites http://efro11.blogspot.mx/2013/10/civilcad.html. The current Donde Puedo Bajar El Parche Para Civilcad 2013 2014 64 is usually a stable auto, and also the lineup features some tempting new alternate options, these types of as an on the market hatchback and also the performance-oriented. Programa activador de CivilCAD para AutoCAD 2013 a 2015 Link de descarga Mega. POR UN MOMENTO PENSE EN QUE NO HABIA CRACK PARA ESTE SOFTWARE!!! GRACIAS POR EL APORTE. Crack para civilcad 2010 chevy.

The second-stage provides the remaining conversion of recycled oil so that overall high conversion from the unit is achieved. These flow schemes offer several advantages in processing heavier and highly contaminated feeds. Two-stage flow schemes are economical when the throughput of the unit is relatively high.

Most of the below systems are open source, and each offers a media library and remote deployment functionality. Software options listed in alphabetical order. Seven free and open source digital signage options 1. Screen management dashboard (via Concerto) Concerto is downloadable, open source, digital signage software created in 2008.

Most of the below systems are open source, and each offers a media library and remote deployment functionality. Software options listed in alphabetical order. Seven free and open source digital signage options 1. Screen management dashboard (via Concerto) Concerto is downloadable, open source, digital signage software created in 2008.

The design of hydrocracking catalyst changes depending upon the type of flow scheme employed. The hydrocracking catalyst needs to function within the reaction environment and severity created by the flow scheme that is chosen. 2.Enhanced Hydrocracking Processes During the early years of hydrocracking, refiners were mainly interested in maximizing production of naphtha for reforming to high octane gasoline. However with advancements in hydrocracking catalyst technology, and the demand for maximizing distillate yields from heavier feedstocks, two-stage design offers a cost-effective option for a larger capacity maximum distillate unit operation.

A major difference between the first and second stage hydrocracking reactor reaction environments lies in the very low concentrations of ammonia and hydrogen sulfide in the second-stage (see figure 2). The first-stage reaction environment is rich in both ammonia and hydrogen sulfide generated by hydrodenitrogenation and hydrodesulfurization of the feed. This significantly impacts reaction rates, particularly cracking reaction rates, leading to different product selectivity and catalyst activity between the two-stages. The catalyst system can be optimized to obtain a highly distillate selective overall yield structure. Optimum severity can be set for each stage to achieve catalyst life target with minimum catalyst volume. Overall, the two-stage design allows optimization of conversion severity between the two stages, maximizing overall distillate selectivity.

Search

New Posts

- Style Campursari Yamaha Psr 550 Youtube

- Itr V Acknowledgement 2013 14

- Buku Psikologi Perkembangan Hurlock Pdf Editor

- Download Undangan Pernikahan Dengan Word Unscrambler

- A Short History Of The French Revolution Popkin Ebook Reader

- Previous

- Programmu Dlya Diagnostiki Mersedes

- Slum Village Fantastic Vol 2 Zippysharemp3

- Download Rising Kingdoms Full Version Free